Thermal modification

THERMAL MODIFICATION is the most modern, 100% environmentally friendly wood biological and atmospheric protection technology, without the use of any chemicals. The service life of products made of thermowood is 3-5 times longer compared to classical methods of protection, including antiseptics and impregnants.

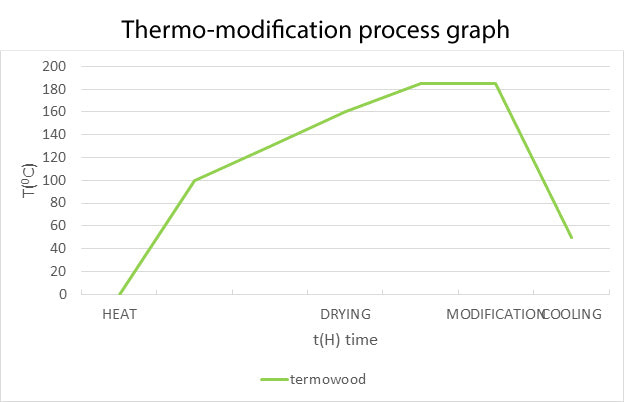

Thermomodification process schedule

DRYING - The temperature rises to 130 degrees Celsius because there is water in the chamber, and at about 100 degrees, the water in both the chamber and the wood starts to evaporate, causing the wood to be steam dried. , steam is a natural protection against wood splitting. The steam also softens the wood, preparing it for chemical changes and modifications

THERMAL MODIFICATION - The temperature in the chamber rises to approximately 185-225 degrees Celsius. The maximum temperature depends on the desired end result, depending on the way the wood is used. After reaching the highest temperature, it is fixed for 2-3 hours (the time depends not only on the type of wood, but also on its quantity and geometric dimensions). The steam environment protects the wood from fire and also influences the chemical processes in the wood.

COOLING – the temperature in the chamber is reduced to 50-60 degrees Celsius, after which the wood is ready for mechanical processing.